In the rapidly evolving world of automation, understanding the key components that drive these systems is crucial. This article delves into four essential elements that play pivotal roles in modern automation: CNC pendants, 8 channel relay modules, automation control devices, and programmable relays. Each of these components offers unique functionalities that enhance efficiency, precision, and control in various industrial and technological applications. By exploring the features and benefits of these components, we aim to provide a comprehensive overview of their importance and how they interconnect to form robust automation systems. Whether you’re an engineer, technician, or enthusiast, gaining insights into these elements will equip you with the knowledge to leverage their capabilities effectively.

CNC Pendant: Enhancing Precision and Control

A CNC pendant is an essential tool in the realm of computer numerical control (CNC) machining. This handheld device allows operators to control CNC machines with ease and precision, providing an interface that enhances the overall machining process. The primary function of a CNC pendant is to facilitate manual control over the machine’s movements, making it an invaluable asset for tasks that require high levels of accuracy.

One of the significant advantages of using a CNC pendant is its ability to improve operational efficiency. By allowing operators to control the machine remotely, a CNC pendant reduces the need for constant monitoring at the machine itself. This remote capability not only saves time but also enhances safety, as operators can maintain a safe distance from the machine during operations. Furthermore, the ergonomic design of CNC pendants ensures that they are user-friendly, with intuitive controls that simplify complex tasks.

CNC pendants are equipped with various features that cater to the specific needs of CNC machining. For instance, they often include a jog wheel, which allows for precise control of the machine’s axes. This feature is particularly useful for fine-tuning the position of the tool or workpiece. Additionally, many CNC pendants come with customizable buttons, enabling operators to program shortcuts for frequently used commands, thus streamlining the workflow.

Another critical aspect of CNC pendants is their compatibility with different types of CNC machines. Whether used with milling machines, lathes, or routers, a CNC pendant can significantly enhance the versatility and functionality of these machines. This compatibility ensures that operators can achieve consistent results across various applications, making the CNC pendant a versatile tool in any machining environment.

In conclusion, a CNC pendant is a vital component in CNC machining, offering enhanced control, precision, and efficiency. Its user-friendly design and versatile features make it an indispensable tool for operators looking to optimize their machining processes. By incorporating a CNC pendant into your workflow, you can achieve higher levels of accuracy and productivity, ultimately leading to better outcomes in your manufacturing endeavors.

8 Channel Relay Module: Versatile and Efficient Switching

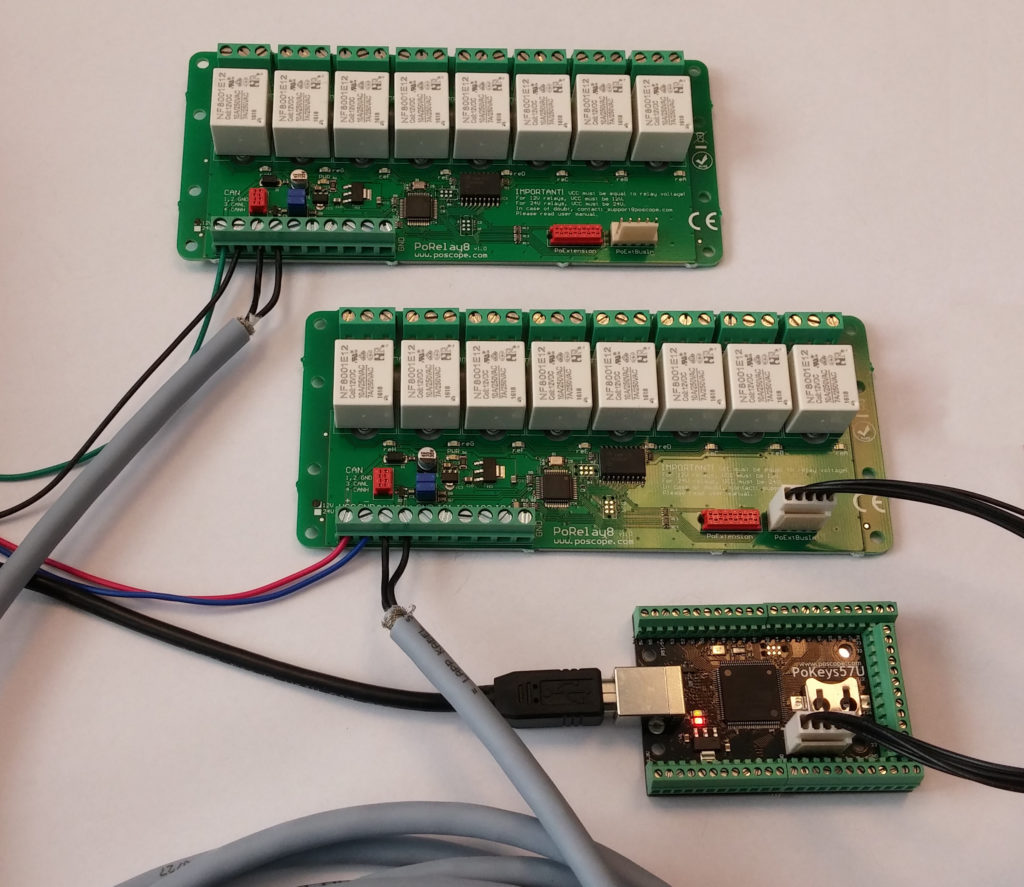

An 8 channel relay module is a highly versatile component in the world of automation and control systems. This module consists of eight individual relays, each capable of controlling different circuits independently. The primary function of an 8 channel relay module is to provide a means for switching multiple devices on and off, making it an indispensable tool for complex automation projects.

One of the key advantages of using an 8 channel relay module is its ability to manage multiple devices simultaneously. This capability is particularly beneficial in applications where precise control over various outputs is required. For instance, in an automated home lighting system, an 8 channel relay module can control different light fixtures, allowing for customized lighting scenes and schedules. This level of control not only enhances convenience but also contributes to energy efficiency.

The 8 channel relay module is also known for its ease of integration with various control systems. Whether interfacing with a microcontroller, PLC (Programmable Logic Controller), or an Arduino board, these modules are designed to work seamlessly with different platforms. This compatibility ensures that the 8 channel relay module can be incorporated into a wide range of projects, from simple DIY electronics to sophisticated industrial automation systems.

Durability and reliability are other significant attributes of an 8 channel relay module. These modules are built to withstand high currents and voltages, ensuring consistent performance even in demanding environments. The use of high-quality materials and robust construction techniques contributes to the longevity of the module, reducing the need for frequent replacements and maintenance.

Furthermore, the 8 channel relay module often comes with features that enhance its usability and functionality. For example, many modules include LED indicators that provide visual feedback on the status of each relay, making it easy to monitor and troubleshoot the system. Additionally, the relays are typically optically isolated, protecting the control circuits from voltage spikes and electrical noise, thus ensuring safe and reliable operation.

In summary, the 8 channel relay module is a versatile and efficient switching solution for various automation and control applications. Its ability to manage multiple devices, ease of integration, and robust design make it a valuable component in any automation setup. By incorporating an 8 channel relay module into your project, you can achieve greater control, flexibility, and reliability, ultimately enhancing the performance and efficiency of your system.

Automation Control Device: Centralizing and Streamlining Operations

An automation control device is a pivotal element in the orchestration of automated systems. These devices serve as the central hub for managing and regulating various processes within an industrial or technological setting. The primary function of an automation control device is to coordinate the operations of different components, ensuring that they work in harmony to achieve desired outcomes.

One of the most significant benefits of using an automation control device is its ability to centralize control. In complex systems where multiple processes need to be managed simultaneously, an automation control device acts as the brain, processing inputs and directing outputs efficiently. This centralization streamlines operations, reducing the likelihood of errors and enhancing overall system reliability. For example, in a manufacturing plant, an automation control device can manage conveyor belts, robotic arms, and other machinery, ensuring that each component operates in sync.

Automation control devices are designed to be highly versatile, capable of integrating with various sensors, actuators, and other peripheral devices. This versatility allows them to be used in a wide range of applications, from simple home automation systems to complex industrial processes. The ability to connect with different devices also enables the automation control device to collect and analyze data from multiple sources, providing valuable insights that can be used to optimize operations and improve efficiency.

The user interface of an automation control device is another critical aspect of its functionality. Modern devices often come with intuitive, user-friendly interfaces that make it easy for operators to monitor and control different processes. These interfaces can range from simple touchscreens to advanced graphical user interfaces (GUIs) that provide real-time data visualization and control options. The ease of use ensures that operators can quickly adapt to the system, reducing training time and enhancing productivity.

Safety and reliability are also paramount when it comes to automation control devices. These devices are typically equipped with fail-safe mechanisms and redundancy features that ensure continuous operation even in the event of a component failure. This reliability is crucial in environments where downtime can lead to significant losses, such as in manufacturing or critical infrastructure systems. Additionally, automation control devices often include robust security measures to protect against unauthorized access and cyber threats, ensuring the integrity and safety of the automated system.

In conclusion, an automation control device is a central and indispensable component in modern automation systems. Its ability to centralize and streamline operations, integrate with various devices, and provide user-friendly interfaces makes it an invaluable tool for optimizing performance and efficiency. By leveraging the capabilities of an automation control device, organizations can achieve higher levels of automation, reliability, and safety in their operations.

Programmable Relay: Customizable Control for Advanced Automation

A programmable relay is a sophisticated device designed to offer customizable control over electrical circuits in automation systems. Unlike traditional relays that operate based on predefined conditions, a programmable relay provides the flexibility to set complex control logic, making it an essential component for advanced automation applications. The primary function of a programmable relay is to execute user-defined programs, allowing for precise control over various processes.

One of the key benefits of using a programmable relay is its adaptability. This device can be programmed to perform a wide range of tasks, from simple on/off switching to intricate sequences of operations. For instance, in an industrial setting, a programmable relay can be used to control machinery, manage lighting systems, or coordinate safety mechanisms. The ability to tailor the relay’s functionality to specific needs enhances the overall efficiency and effectiveness of the automation system.

The programming of a programmable relay is typically done through user-friendly software interfaces. These interfaces allow operators to create and modify control programs with ease, often using graphical programming languages that simplify the process. This accessibility ensures that even operators with limited programming experience can develop and implement effective control strategies. Additionally, the software often includes diagnostic tools that help troubleshoot issues and optimize performance.

Another significant advantage of programmable relays is their scalability. These devices can be integrated into larger automation systems, allowing for the expansion and enhancement of existing setups. Whether used in small-scale applications or extensive industrial networks, programmable relays provide a scalable solution that can grow with the needs of the operation. This scalability is particularly beneficial in dynamic environments where requirements can change over time.

Reliability is also a critical feature of programmable relays. Built to withstand harsh industrial conditions, these relays are designed for durability and long-term performance. They often include features such as fault detection and automatic recovery, ensuring continuous operation even in the face of potential disruptions. This reliability minimizes downtime and maintenance costs, contributing to the overall productivity and cost-effectiveness of the automation system.

Furthermore, programmable relays offer enhanced communication capabilities. Many models are equipped with communication ports that enable integration with other devices and systems. This connectivity allows for real-time data exchange and remote monitoring, providing operators with greater visibility and control over their automation processes. The ability to connect with other devices also facilitates the implementation of more complex control schemes, further expanding the versatility of programmable relays.

In conclusion, a programmable relay is a powerful and flexible tool in advanced automation systems. Its customizable control logic, user-friendly programming interfaces, scalability, reliability, and enhanced communication capabilities make it an indispensable component for modern automation. By incorporating programmable relays into your automation strategy, you can achieve precise, efficient, and reliable control over your processes, driving improvements in performance and productivity.

Conclusion

In the intricate landscape of modern automation, understanding the key components that drive these systems is crucial for optimizing performance and achieving desired outcomes. This article has explored four essential elements: CNC pendants, 8 channel relay modules, automation control devices, and programmable relays, each playing a vital role in enhancing control, precision, and efficiency in various applications.

A CNC pendant is indispensable in CNC machining, offering enhanced manual control and improving operational efficiency and safety. Its user-friendly design and versatile features make it a critical tool for achieving high levels of accuracy in machining processes.

The 8 channel relay module stands out for its ability to manage multiple devices simultaneously, making it a versatile solution for complex automation projects. Its ease of integration, durability, and robust design ensure reliable performance across various applications, from home automation to industrial systems.

An automation control device serves as the central hub for managing and regulating processes within automated systems. Its ability to centralize control, integrate with diverse devices, and provide user-friendly interfaces makes it a cornerstone of efficient and reliable automation, enhancing overall system performance.

Lastly, the programmable relay offers customizable control logic for advanced automation needs. Its flexibility, scalability, and reliability, coupled with enhanced communication capabilities, make it an essential component for sophisticated automation strategies, allowing for precise and efficient control over processes.

Together, these components form the backbone of modern automation systems, each contributing unique functionalities that enhance the overall efficiency, precision, and control. By understanding and leveraging the capabilities of CNC pendants, 8 channel relay modules, automation control devices, and programmable relays, organizations can achieve significant improvements in their automation efforts, driving innovation and productivity in their operations.